Precision Measurement and Process Control with Coriolis Flow Meters

In any industrial process, precision measurement plays a vital role in ensuring quality, safety and efficiency. Accurate and reliable flow measurement is essential for proper process control, and several technologies are available to measure flow, density and viscosity of fluids.

One of the most reliable and versatile measurement technologies is Coriolis flow metering. A Coriolis flow meter works by measuring the mass of a flowing fluid directly, using the principle of Coriolis force. When a fluid flows through a vibrating tube, the tube experiences a slight twisting motion, which is proportional to the mass flow rate. By measuring this motion, the flow rate can be determined with exceptional accuracy, regardless of fluid properties or conditions.

Coriolis meters are highly accurate and can measure both flow rate and density of fluids. They can also provide viscosity measurements and are ideal for applications that require precise flow control and metering. Some of the key advantages of Coriolis flow meters include:

High accuracy: Coriolis meters can achieve accuracy better than +/-0.1%, even under changing process conditions.

Wide range: Coriolis meters can measure flow rates from very low to very high, and can handle a wide range of fluids and viscosities.

Reliance: Coriolis meters are highly reliable and require little maintenance, making them ideal for critical process applications.

Process control: Coriolis meters offer a wealth of process control options, such as batching, dosing and blending, which make them ideal for complex processes.

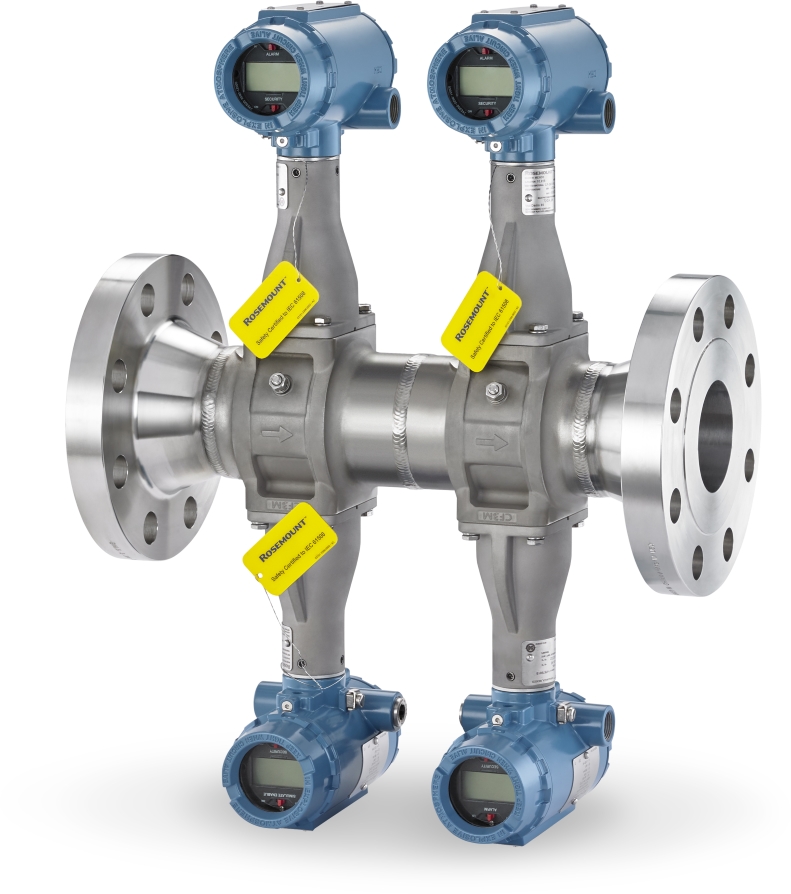

In addition to their accuracy and versatility, Coriolis meters are easy to install and use. Most modern meters feature digital communication and diagnostic capabilities, enabling remote monitoring and control. They can also be integrated with other instruments and systems, such as pressure and temperature sensors, to provide a comprehensive solution for process control and optimization.

When it comes to choosing a Coriolis flow meter, there are several factors to consider, such as:

Fluid properties: Coriolis meters can handle a wide range of fluids, but some fluids may require special tube materials or coatings to prevent corrosion or fouling.

Process conditions: Coriolis meters operate well under most process conditions, but extreme temperatures, pressures or vibrations may require additional measures to protect the meter or maintain accuracy.

Flow range: Coriolis meters come in a range of sizes and flow rates, and the right meter choice depends on the specific application requirements.

Integration: Coriolis meters can be integrated with other sensors and systems, and the choice of meter should consider the compatibility and communication protocols required.

Overall, Coriolis flow meters are a powerful tool for achieving precision measurement, reliability and process control in industrial applications. They offer exceptional accuracy, versatility and reliability, and are ideal for a wide range of applications, from food and beverage to automotive, chemical and oil and gas. By selecting the right Coriolis meter and integrating it effectively with other instruments and systems, companies can optimize their processes, reduce waste and improve quality, while achieving better performance and profitability.