Temperature is one of the most important parameters for measuring and controlling industrial processes. To achieve efficient and safe processes, it is essential to have precise and reliable temperature measurements. Conventional temperature sensors such as thermocouples and resistance temperature detectors (RTDs) have been used in a wide range of applications. However, at high temperatures, these sensors can degrade and become less accurate. This is where Ultrasonic Transducers for High Temperature Applications come in, which can improve the accuracy, reliability and durability of temperature measurements, making them suitable for harsh environments.

Ultrasonic transducers have been used in Non-Destructive Testing (NDT) applications for many years, but only recently have they been applied to temperature measurements in harsh environments where conventional sensors fail. Ultrasonic transducers work by emitting and receiving ultrasonic waves, which travel through a medium and are modulated by the temperature of the medium. By measuring the time delay and phase shift of the ultrasonic waves, temperature measurements can be obtained.

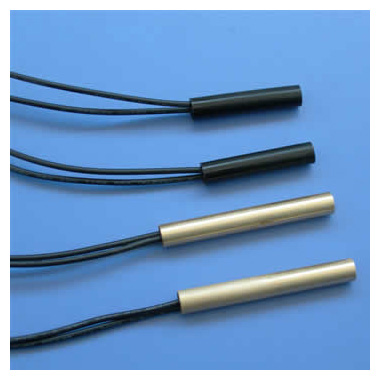

Acoustic Temperature Sensors, as a type of ultrasonic transducer, have recently gained attention for their ability to measure temperature at high temperatures, up to 1000°C, making them suitable for applications in industries such as cement production, steelmaking, and power generation. Compared to traditional temperature sensors, acoustic temperature sensors have many advantages, such as:

1. Accuracy: Acoustic temperature sensors have a high accuracy of ± 0.5°C, which is essential for precise temperature control in industrial processes.

2. Durability: Acoustic temperature sensors are designed to withstand high temperatures, harsh chemicals, and mechanical stress, making them suitable for harsh environments.

3. Stability: Acoustic temperature sensors are stable and reliable, with a long service life, reducing maintenance costs and downtime.

4. Non-invasive: Acoustic temperature sensors are non-invasive, making them suitable for situations where surface temperature measurements are not possible.

Acoustic temperature sensors can be designed as either single or multi-element transducers, depending on the specific application requirements. Single-element transducers are suitable for measuring temperature at a single point, while multi-element transducers can measure temperature at multiple points simultaneously, providing a more detailed temperature distribution profile.

In conclusion, Ultrasonic Transducers for High Temperature Applications, especially Acoustic Temperature Sensors, offer a promising solution for precise, reliable and durable temperature measurements in harsh environments. The advantages of acoustic temperature sensors include high accuracy, durability, stability, and non-invasiveness, which make them ideal for various industrial applications. With ongoing research and development, the potential applications of acoustic temperature sensors are expanding, and they are expected to become an essential tool for temperature measurements in the future.