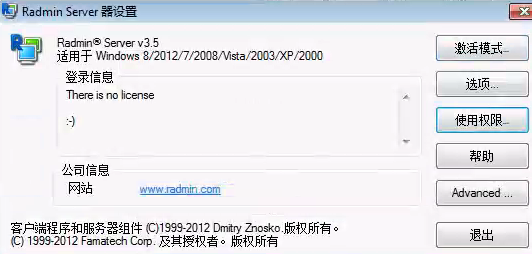

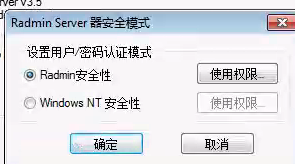

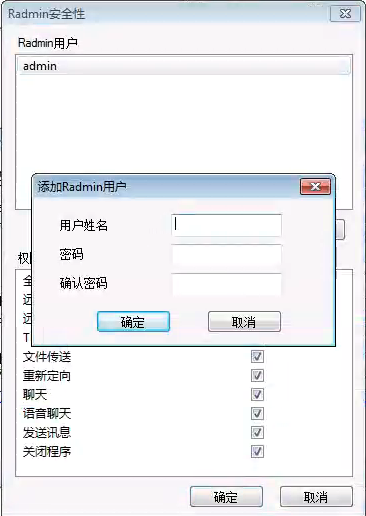

2)Set Radmin, add account and password

2)Set Radmin, add account and password

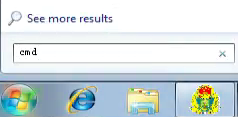

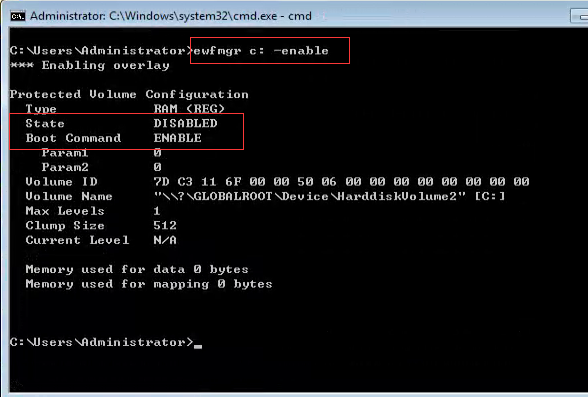

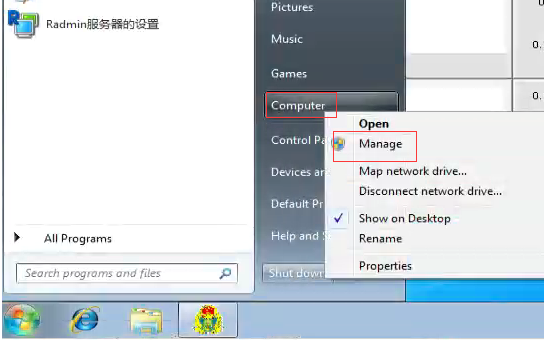

3.1.2 system disk protection 1)Running the CMD instruction to enter the DOS environment.

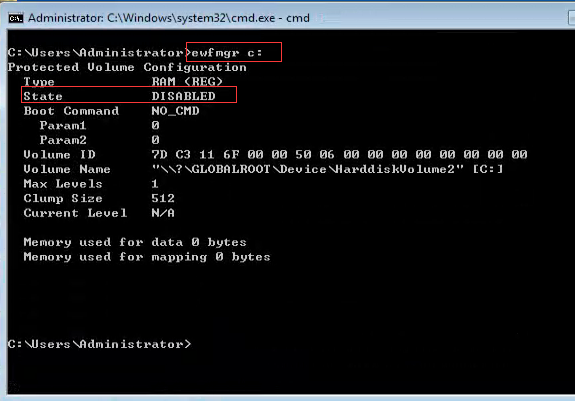

3.1.2 system disk protection 1)Running the CMD instruction to enter the DOS environment.  2)Query EWF protection status (type EWFMGR C: enter) (1)At this time, EWF protection function is on(State = ENABLE)

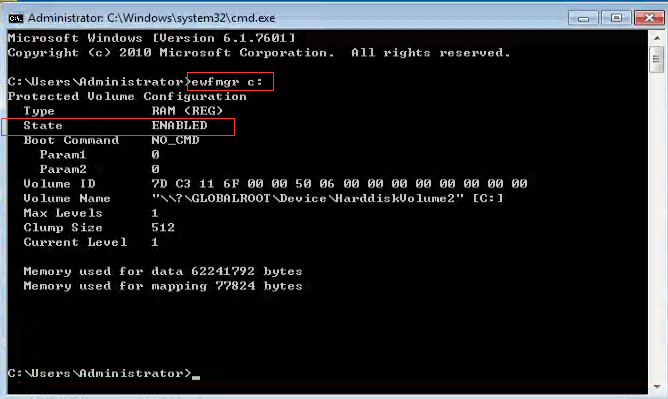

2)Query EWF protection status (type EWFMGR C: enter) (1)At this time, EWF protection function is on(State = ENABLE)  (Type EWFMGR c: -communanddisable -live enter), and state is disabled to indicate that EWF protection is off (2)At this time, EWF protection function is closing (state = disable), no subsequent operation is required.

(Type EWFMGR c: -communanddisable -live enter), and state is disabled to indicate that EWF protection is off (2)At this time, EWF protection function is closing (state = disable), no subsequent operation is required.  (3) After changing the system settings, set EWF to enable

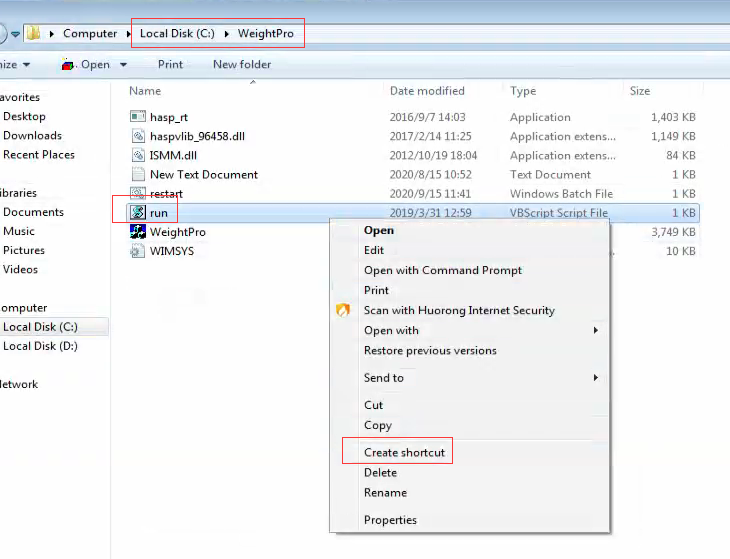

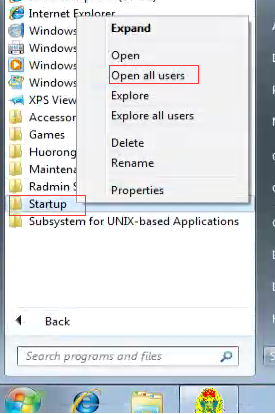

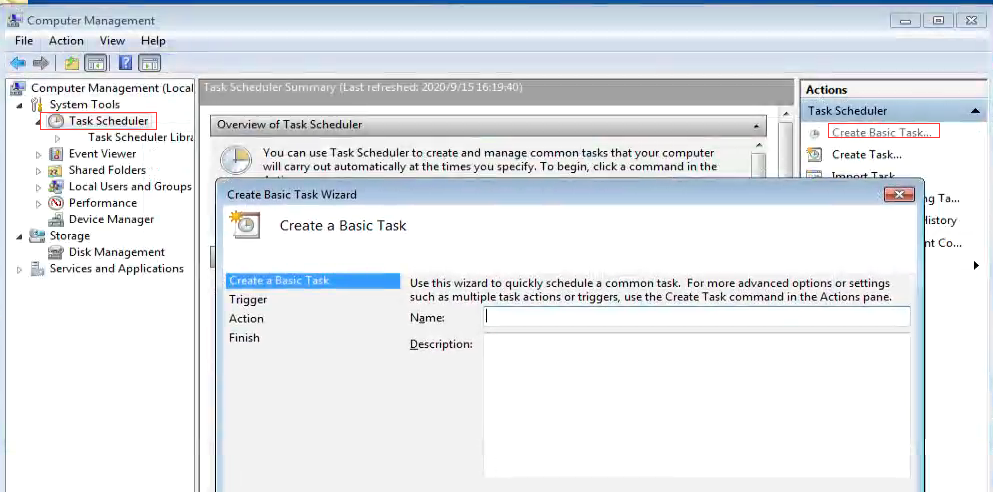

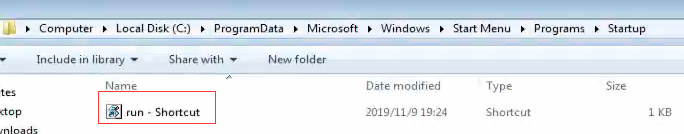

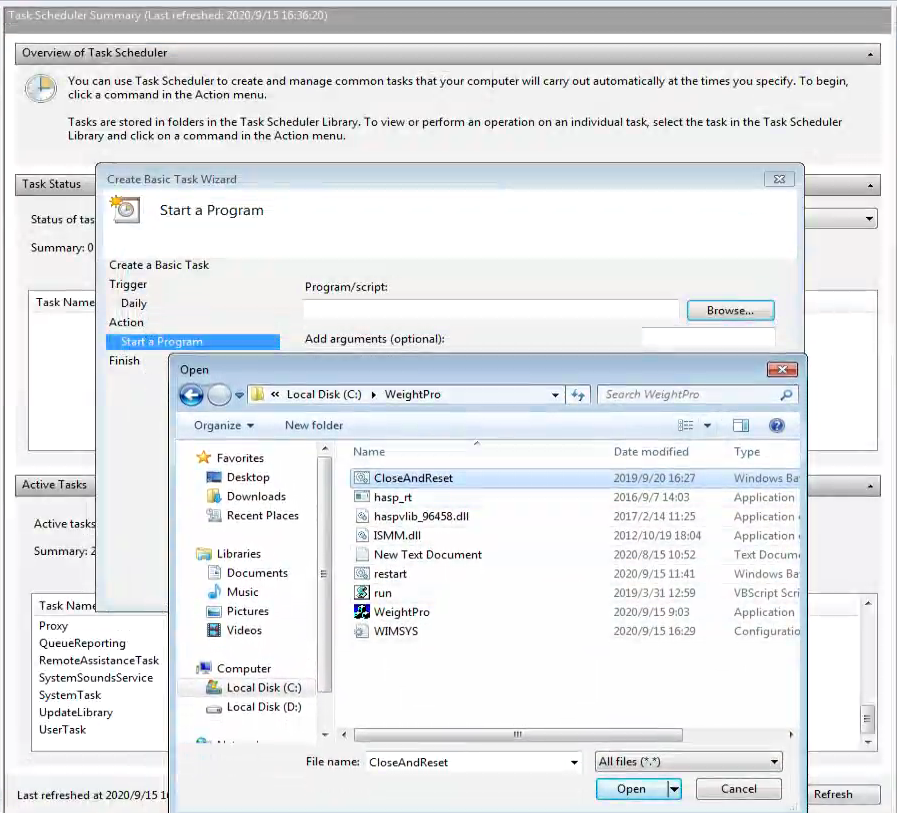

(3) After changing the system settings, set EWF to enable  3.1.3 Create auto start shortcut 1)Create a shortcut to run.

3.1.3 Create auto start shortcut 1)Create a shortcut to run.

1.2.1 system equipment connection The system equipment is mainly composed of system controller, charge amplifier and IO input / output controller

1.2.1 system equipment connection The system equipment is mainly composed of system controller, charge amplifier and IO input / output controller 1.2.2 system controller interface The system controller can connect 3 charge amplifiers and 1 IO controller, with 3 rs232/rs465, 4 USB and 1 network interface.

1.2.2 system controller interface The system controller can connect 3 charge amplifiers and 1 IO controller, with 3 rs232/rs465, 4 USB and 1 network interface. 1.2.1 amplifier interface The charge amplifier supports 4, 8, 12 channels (optional) sensor input, DB15 interface output, and the working voltage is DC12V.

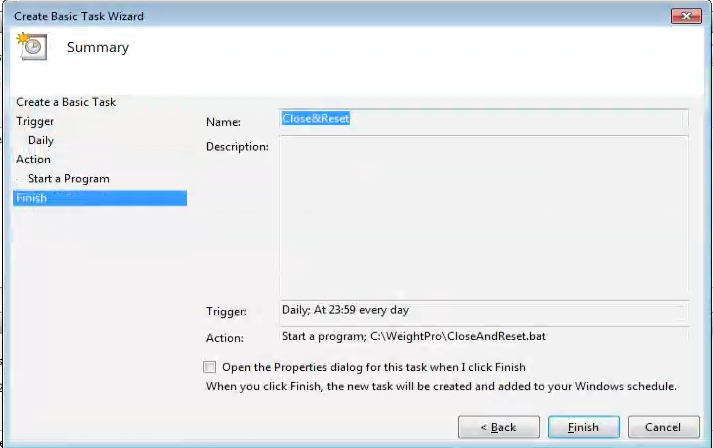

1.2.1 amplifier interface The charge amplifier supports 4, 8, 12 channels (optional) sensor input, DB15 interface output, and the working voltage is DC12V. 1.2.1 I / O controller interface IO input and output controller, with 16 isolated input, 16 isolation output, DB37 output interface, Working Voltage DC12V.

1.2.1 I / O controller interface IO input and output controller, with 16 isolated input, 16 isolation output, DB37 output interface, Working Voltage DC12V.| power | AC220V 50Hz |

| speed range | 0.5km/h~100km/h |

| sale division | d =50kg |

| axle tolerance | ±10% constant speed |

| vehicle accuracy level | 5 class,10class ,2 class(0.5km/h~20km/h) |

| Vehicle separation accuracy | ≥99% |

| Vehicle recognition rate | ≥98% |

| axle load range | 0.5t~40t |

| Processing lane | 5 lanes |

| Sensor channel | 32channels, or to 64 channels |

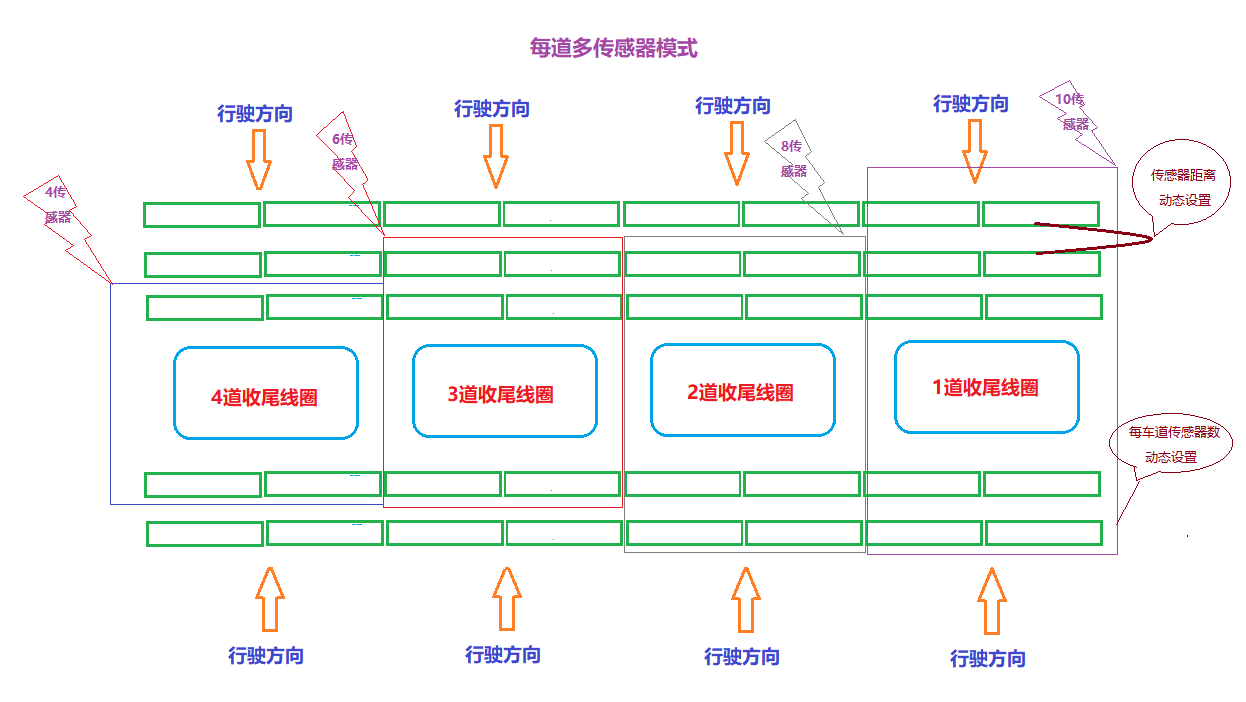

| Sensor layout | Support multiple sensor layout modes, each lane as 2pcs or 16pcs sensor to sent ,support a variety of pressure sensors. |

| Camera trigger | 16channel DO isolated output trigger or network trigger mode |

| Ending detection | 16channel DI isolation input connect coil signal, laser ending detection mode or auto ending mode. |

| System software | Embedded WIN7 operating system |

| Axle identifier access | Support a variety of wheel axle recognizer (quartz, infrared photoelectric, ordinary) to form complete vehicle information |

| Vehicle type identifier access | it supports vehicle type identification system and forms complete vehicle information with length, width and height data. |

| Support bidirectional detection | Support forward and reverse bidirectional detection. |

| Device interface | VGA interface, network interface, USB interface, RS232, etc |

| State detection and monitoring | Status detection: the system detects the status of main equipment in real time, and can automatically repair and upload information in case of abnormal conditions. |

| Remote monitoring: support remote desktop, Radmin and other remote operations, support remote power-off reset. | |

| Data storage | Wide temperature solid state hard disk, support data storage, logging, etc. |

| System protection | Three level WDT support, FBWF system protection, system curing antivirus software. |

| System hardware environment | Wide temperature industrial design |

| Temperature control system | The instrument has its own temperature control system, which can monitor the temperature status of the equipment in real time and dynamically control the fan start and stop of the cabinet |

| Use environment (wide temperature design) | Service temperature: - 40 ~ 85 ℃ |

| Relative humidity: ≤ 85% RH | |

| Preheating time: ≤ 1 minute |

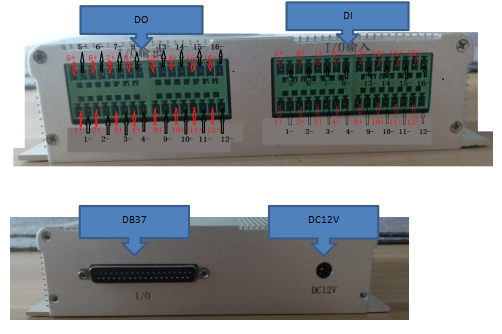

16 channels of DI isolated input, supporting coil controller, laser detector and other finishing equipment, supporting Di mode such as optocoupler or relay input. The forward and reverse directions of each lane share one ending device, and the interface is defined as follows;

16 channels of DI isolated input, supporting coil controller, laser detector and other finishing equipment, supporting Di mode such as optocoupler or relay input. The forward and reverse directions of each lane share one ending device, and the interface is defined as follows;| Ending lane | DI interface port number | note |

| No 1 lane(forward ,reverse) | 1+、1- | If the ending control device is optocoupler output, the ending device signal should correspond to the + and - signals of IO controller one by one. |

| No 2 lane(forward ,reverse) | 2+、2- | |

| No 3 lane(forward ,reverse) | 3+、3- | |

| No 4 lane(forward ,reverse) | 4+、4- | |

| No 5 lane(forward ,reverse) | 5+、5- |

| Lane number | Forward trigger | Tail trigger | Side direction trigger | Tail side direction trigger | Note |

| No1 lane (forward) | 1+、1- | 6+、6- | 11+、11- | 12+、12- | The trigger control end of the camera has a + - end. The trigger control end of the camera and the + - signal of IO controller should correspond one by one. |

| No2 lane(forward) | 2+、2- | 7+、7- | |||

| No3 lane(forward) | 3+、3- | 8+、8- | |||

| No4 lane(forward) | 4+、4- | 9+、9- | |||

| No5 lane(forward) | 5+、5- | 10+、10- | |||

| No1 lane(reverse) | 6+、6- | 1+、1- | 12+、12- | 11+、11- |

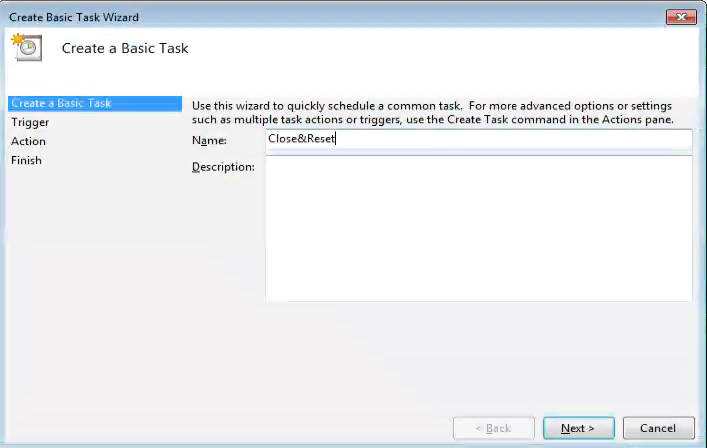

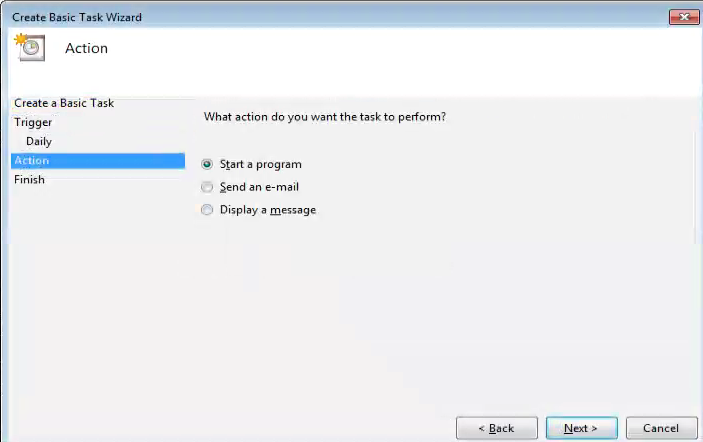

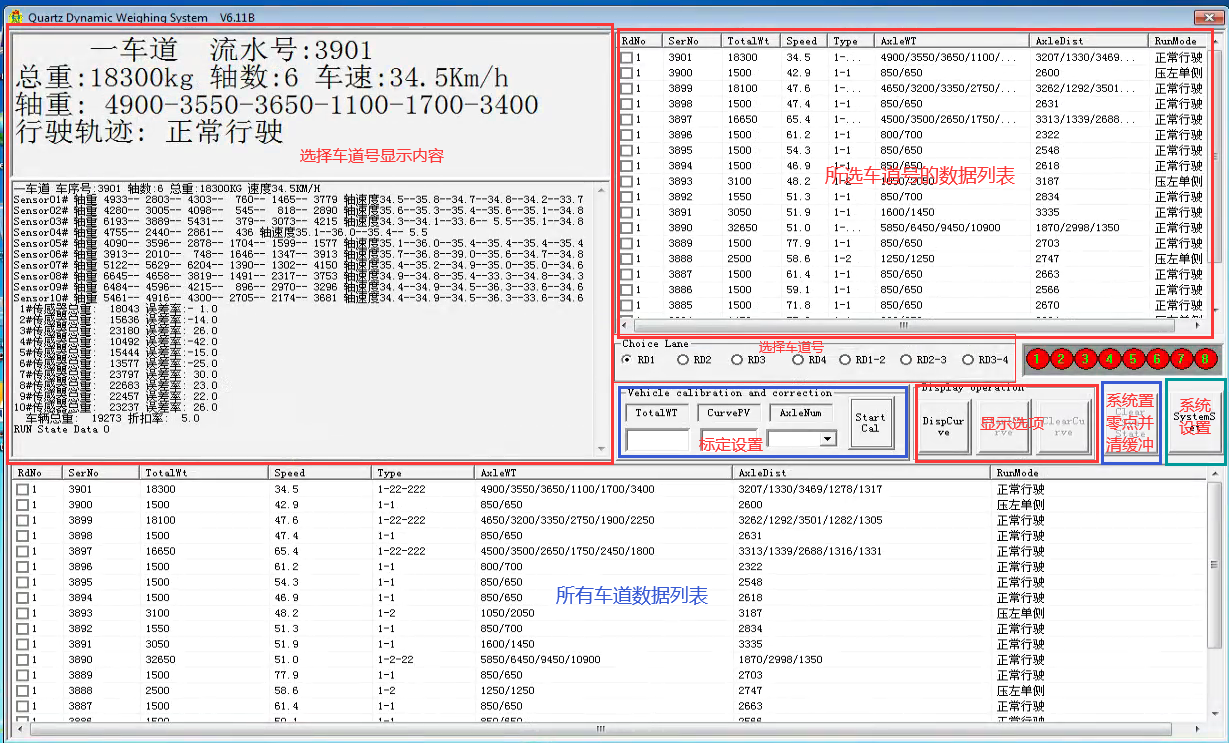

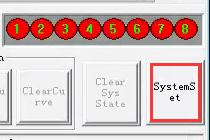

3.3 System parameter setting 3.3.1 System initial parameter setting. (1)Enter the system settings dialog box

3.3 System parameter setting 3.3.1 System initial parameter setting. (1)Enter the system settings dialog box  (2) Setting parameters

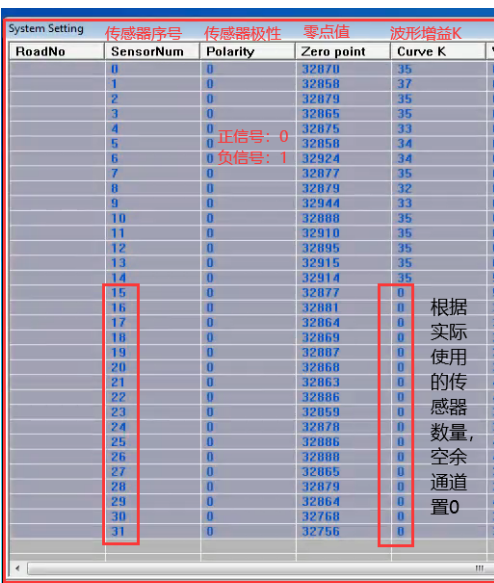

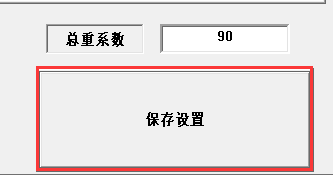

(2) Setting parameters  a.Set the total weight coefficient as 100

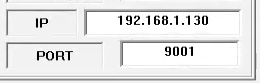

a.Set the total weight coefficient as 100  b.Set IP and port number

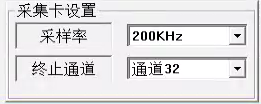

b.Set IP and port number  c.Set the sample rate and channel

c.Set the sample rate and channel  Note: when updating the program, please keep the sampling rate and channel consistent with the original program. d.Parameter setting of spare sensor

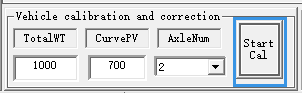

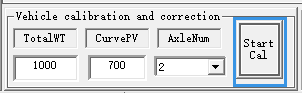

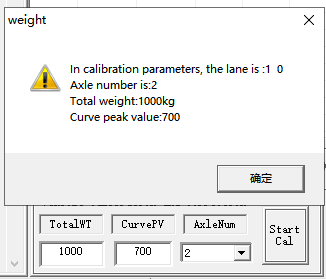

Note: when updating the program, please keep the sampling rate and channel consistent with the original program. d.Parameter setting of spare sensor  4. Enter the calibration setting

4. Enter the calibration setting

5.When the vehicle passes through the sensor area evenly (the recommended speed is 10 ~ 15km / h), the system generates new weight parameters 6.Reload new weight parameters. (1)Enter system settings.

5.When the vehicle passes through the sensor area evenly (the recommended speed is 10 ~ 15km / h), the system generates new weight parameters 6.Reload new weight parameters. (1)Enter system settings.  (2)Click Save to exit.

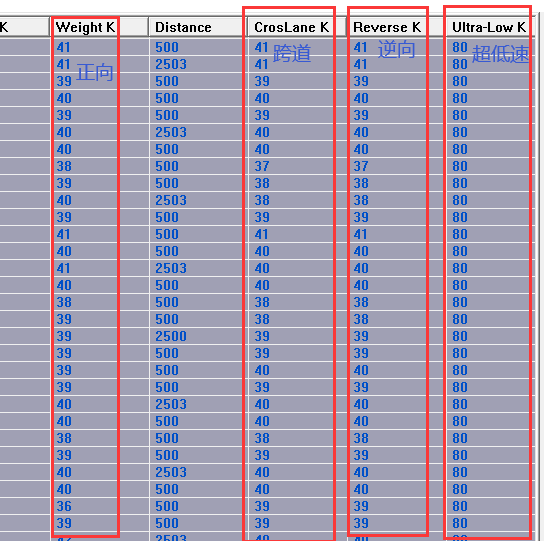

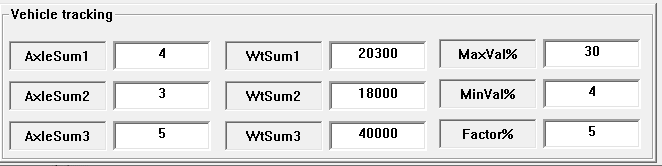

(2)Click Save to exit. 5. Fine tuning of system parameters According to the weight generated by each sensor when the standard vehicle passes through the system, the weight parameters of each sensor are adjusted manually. 1.Set up the system.

5. Fine tuning of system parameters According to the weight generated by each sensor when the standard vehicle passes through the system, the weight parameters of each sensor are adjusted manually. 1.Set up the system.  2.Adjust the corresponding K-factor according to the driving mode of the vehicle. They are forward, cross channel, reverse and ultra-low speed parameters.

2.Adjust the corresponding K-factor according to the driving mode of the vehicle. They are forward, cross channel, reverse and ultra-low speed parameters.  6.System detection parameter setting Set the corresponding parameters according to the system detection requirements.

6.System detection parameter setting Set the corresponding parameters according to the system detection requirements.  TCPIP communication mode, sampling XML format for data transmission.

TCPIP communication mode, sampling XML format for data transmission. - Vehicle entering: the instrument is sent to the matching machine, and the matching machine does not reply.

| Detective head | Data body length (8-byte text converted to integer) | Data body (XML string) |

| DCYW | <root type=”carcome”> <data deviceno=Instrument number roadno=Road no recno=Data serial number /> </root> |

- Vehicle leaving: the instrument is sent to the matching machine, and the matching machine does not reply

| head | (8-byte text converted to integer) | Data body (XML string) |

| DCYW | <root type=”cargo”> <data deviceno=Instrument number roadno=Road No recno= Data serial number /> </root> |

- Upload of weight data: the instrument is sent to the matching machine, and the matching machine does not reply.

| head | (8-byte text converted to integer) | Data body (XML string) |

| DCYW | <root type=”weight”> <data deviceno= Instrument number roadno=Road no: recno=Data serial number kroadno=Cross the road sign; do not cross the road to fill in 0 speed=speed; Unit kilometer per hour weight= total weight: unit: Kg axlecount=Number of axes; temperature= temperature; maxdistance=The distance between the first axis and the last axis, in millimetres axlestruct=Axle structure: for example, 1-22 means single tire on each side of the first axle, double tire on each side of the second axle, double tire on each side of the third axle, and the second axle and the third axle are connected weightstruct=Weight structure: for example, 4000809000 means 4000kg for the first axle, 8000kg for the second axle and 9000kg for the third axle distancestruct=Distance structure: for example, 40008000 means that the distance between the first axis and the second axis is 4000 mm, and the distance between the second axis and the third axis is 8000 mm diff1=2000 is the millisecond difference between the weight data on the vehicle and the first pressure sensor diff2=1000 is the millisecond difference between the weight data on the vehicle and the ending length=18000; vehicle length; mm width=2500; vehicle width; unit: mm height=3500; vehicle height; unit mm /> </root> |

- Equipment status: the instrument is sent to the matching machine, and the matching machine does not reply.

| Head | (8-byte text converted to integer) | Data body (XML string) |

| DCYW | <root type=”weightstatus”> <data deviceno=Instrument number code=”0” Status code, 0 indicates normal, other values indicate abnormal msg=”” State description /> </root> |